Residential construction projects require airtight building envelopes with continuous insulation to meet sustainability goals. Foamed glass aggregate provides reliable subslab insulation for new construction and deep-energy retrofits, eliminating petrochemical-based materials from foundation assemblies. With easy installation, consistent R-value, and competitive pricing, foamed glass aggregate supports high performance homes, Passive House projects, and standard residential construction.

90% lighter than crushed stone, making it easy to install for builders and DIY users alike.

R1.7 per inch eliminates thermal bridging with continuous insulation for energy efficiency.

Up to 125 psi once compacted, maintains slab stability, and supports structural loads.

Ensures consistent performance while resisting moisture buildup, rot, pest, and mold.

Non-toxic and Red List Free inputs ensure no leaching into nearby soils or environments.

Cost-competitive replacement for rigid foam insulation and crushed stone.

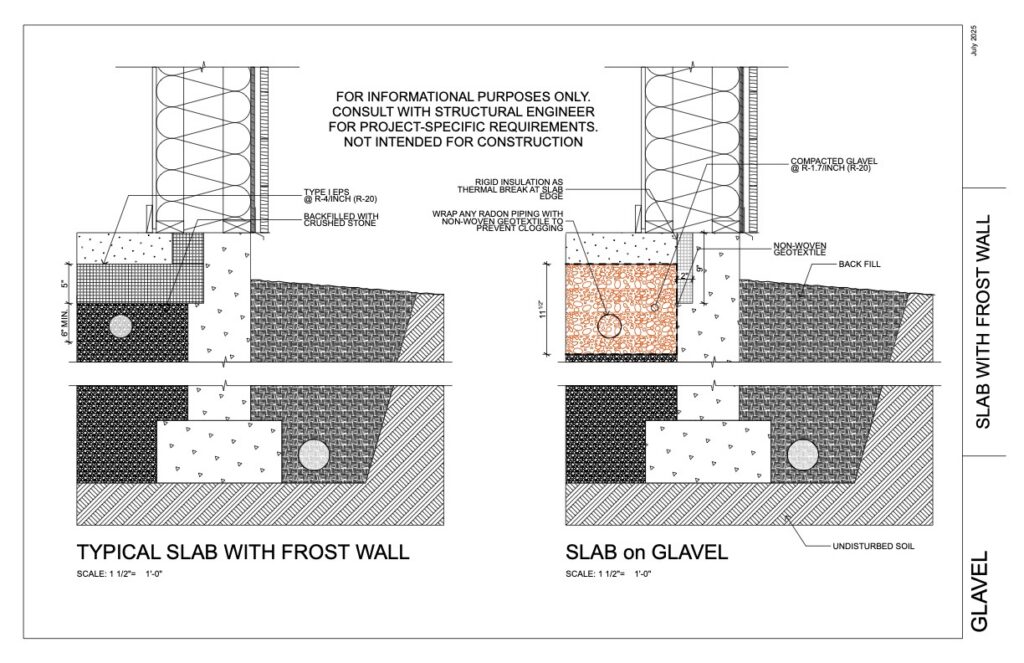

A typical slab-on-grade assembly with foamed glass aggregate consists of the following layers from top to bottom:

This assembly eliminates the traditional layers of crushed stone for drainage and rigid foam boards for insulation, consolidating both functions into the foamed glass aggregate layer. The result is simpler construction, fewer materials to coordinate, and continuous thermal performance without interruption. For frost-protected shallow foundations, foamed glass aggregate can be used both beneath the slab and as insulated backfill around the perimeter, creating a continuous insulated envelope that protects against frost heaving while maintaining thermal performance.

Foam glass gravel is made to meet diverse engineering and design standards required by the construction industry.

Test Name | Standard | Value |

|---|---|---|

Weight (per cubic foot) | 10 lbs | 100 lbs |

Compressive Strength | 130-140 psi | 100+ psi |

Drainage | Free-draining | Free-draining |

Standard Equipment | Standard Equipment | Special Handling |

Durability | High | High |

No. Glavel sells foamed glass aggregate direct-to-consumer. Deliveries come from Glavel’s manufacturing plant in Vermont.

Glavel’s foamed glass aggregate’s R-value is 1.7 per inch. It does not absorb moisture, so the R-value remains stable even in damp conditions.

Foamed glass aggregate is delivered on palletized 3 cubic yard bags via 53’ flatbeds or 26’ box trucks. Bags come with straps at the top and a spout bottom for easy installation.

Pickups can be arranged from the Glavel facility in Essex, Vermont. Customers must schedule in advance and bring a vehicle rated for the weight and volume. The Glavel Operations Team will assist with loading.

Yes. Foamed glass aggregate supports passive radon systems. We recommend wrapping radon pipes with geotextile to maintain airflow. Active systems may slightly impact thermal performance and should be reviewed with your energy modeler if insulation levels are critical.

Standard equipment can install foamed glass aggregate on residential sites. Use rakes to level the material, then use a lightweight vibratory plate compactor (<200 lbs) to achieve even compaction. 4-5 complete passes will achieve the necessary 25% compaction. Avoid heavy tampers or compactors, which are too heavy to successfully compact foamed glass aggregate.

Yes. Foamed glass aggregate can be used to insulate the exterior of foundation walls as loose or compacted fill as long as it is capped and not left exposed.

Foamed glass aggregate can be used beneath footings in many applications when properly evaluated. With compressive strength of 115 – 125 psi when compacted, it’s suitable for many residential loads. We recommend working with your engineer to verify suitability for your specific loading conditions.

Each 3 cubic yard supersack weighs roughly 900 lbs.